Boston, MA ~ 1899

Containing five floors of softwood joists, Boston's 148 West Concord Street was a prolific and hyper-local source of reclaimed wood.

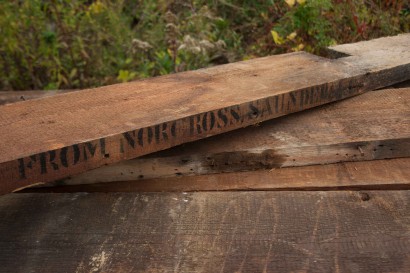

The 4,000 square foot South End brownstone was framed in a classic mix of timber and balloon-framing styles, with large posts and beams joined via mortise, tenon, and peg, and smaller stud assemblies separating rooms and walls. All of the floor joists were sawn by Lowell-based Saunders, Norcross, and Co., a great sawmill and lumber distributer in its time.

In 1845, Nicholas G. Norcross, a Penobscot river lumberman dubbed 'The New England Timber King', founded Norcross, Saunders, and Co. in Lowell with associate John Fiske. Originally operating as the Fiske & Norcross company, the company built two dams on the Merrimack River, recovered from two fires, and eventually expanded to Lawrence, MA. When Nicholas Norcross died in 1860, the business passed on to I.W. Norcross, N.W. Norcross, and Charles W. Saunders, ushering in the era of Norcross, Saunders, and Co. It was in this period that the floor joists for 148 West Concord Street were sawn on massive circular and band saws driven by Merrimack River waterpower.

These particular Norcross-sawn floor joists were destined to support the feet of a great Boston family. In 1884, John M. Falvey, deputy clerk of Boston's Ward 16, Precinct 4 election offices, resided at 148 Concord. It was likely that Falvey was related by marriage to 148 Concord's next (and most illustrious) tenant: Mr. James Maurice Prendergast, of Prendergast family fame and fortune.

James Maurice, a successful businessman, headed an eponymous cotton trading company and sat on the boards of the Boston Elevated Railroad Corp., the Boston and Maine Railroad, the Hamilton Woolen Company, the New England Trust Company, the Second National Bank, and the Commonwealth Trust Company. He was also a collector of fine art and a member of the Boston Parks Commission.

The building's beautiful brick and stone facade will be restored and preserved, while the interior of the building is being gut-renovated. As the softwood floor joists were dropped out and replaced (one story at a time), the timbers were salvaged by Longleaf Lumber for re-milling into flooring, paneling and other reclaimed wood products.